top of page

Search

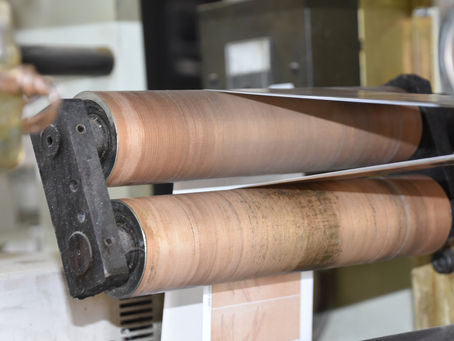

The Role of Nip Rollers in High Speed Production Systems

Nip rollers play a central role in high-speed production systems by applying consistent and controlled pressure between two surfaces. Whether used in printing, laminating, coating, or material converting, the performance of a nip roller directly affects product quality, throughput, and operational stability.

Ben Perren

Nov 29, 20253 min read

Extruded Rubber for Rubber Rollers in Flexo

In flexographic printing, achieving crisp, consistent quality across high-speed runs depends critically on rubber rollers. These rollers, when fabricated with precision and durability, become pivotal to operational success. At the heart of high-performance rollers lies extruded rubber, a material choice that enhances reliability, consistency, and print fidelity.

Ben Perren

Sep 9, 20253 min read

Replacement Pinch Rollers in Flexographic Printing: Why Precision Matters

At RollerTec Inc., we specialize in custom-manufactured and replacement pinch rollers engineered specifically for the demands of flexographic equipment. From wide-web packaging lines to narrow-web label presses, our solutions support improved substrate control, reduced waste, and better print outcomes.

Carol Mercer

Jun 7, 20254 min read

How Nip Roller Pressure Affects Print Quality

This technical deep dive explains how nip pressure interacts with other components in your press system—and how proper calibration can improve print outcomes and reduce defects. You can choose from a variety of lengths and widths of nip rollers to suit specific needs.

Ben Perren

May 11, 20254 min read

bottom of page